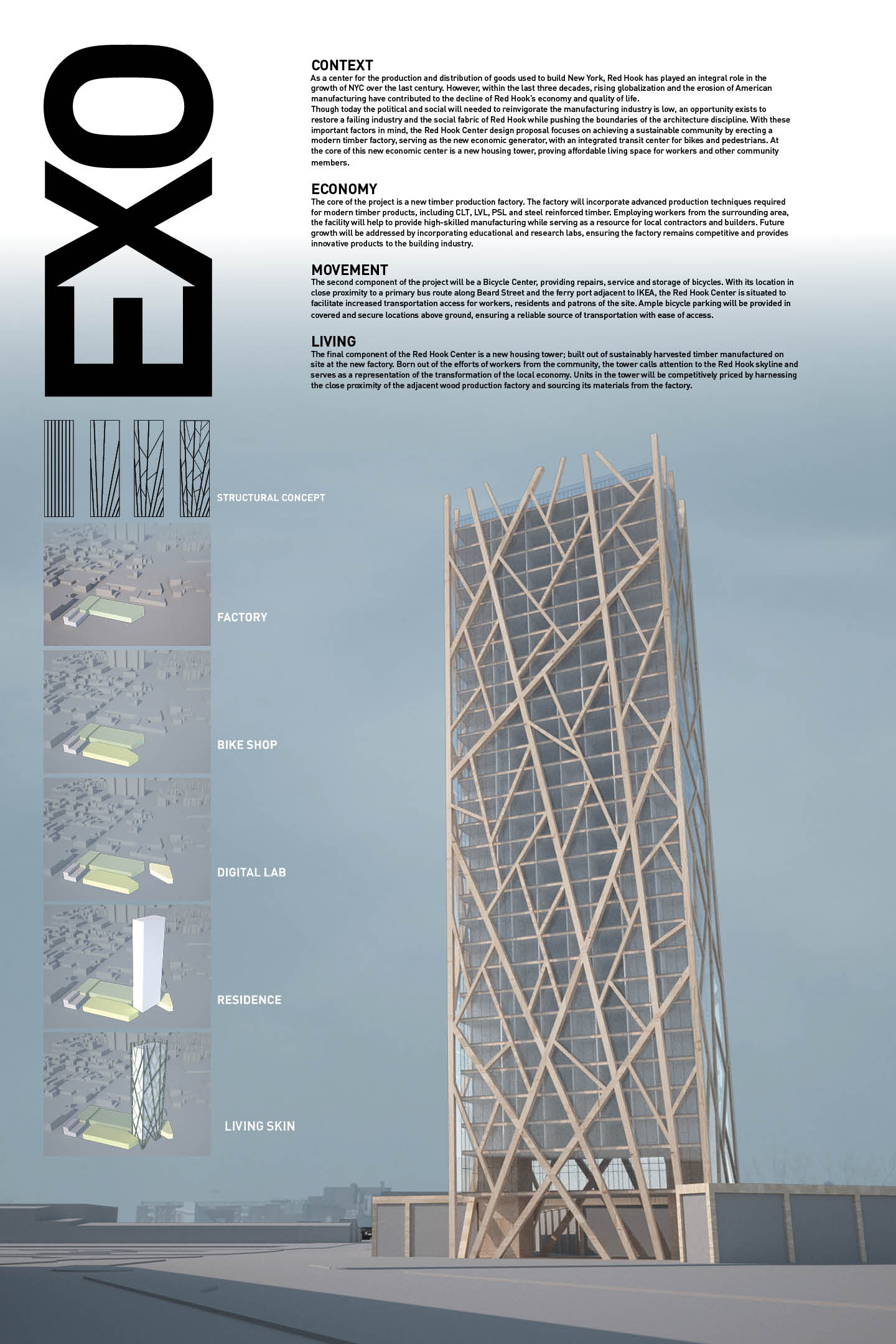

Final review is complete and even though there's more work to be done, it's a relief to have reached this milestone for the semester. Above are the boards I presented today, and though I should have four, I chose to consolidate to three boards to condense the information to be more easily read.

ACSA

Final Stretch /

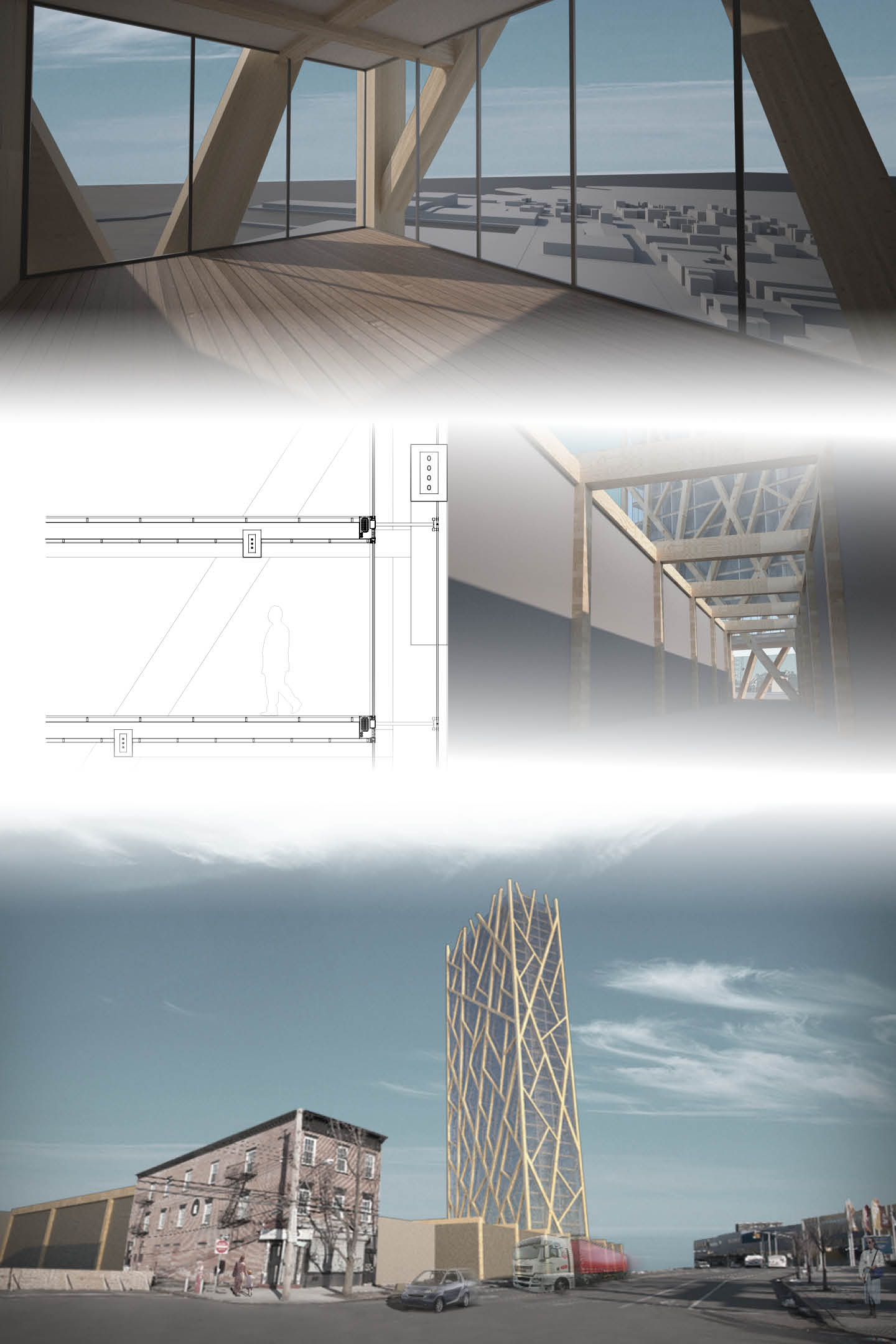

Just under one week until the final review for the Timber Studio and the design for the exoskeleton is complete. My intention is to show that the structure is relatively autonomous while also exploiting the specific performance of wood's structure.

The next week will be focused on completing the model and drawings for the presentation boards. Lots of clarity is needed to present the ideas in a cohesive way, so my focus will be on clean renderings and diagrams for the boards.

Structural Revisions /

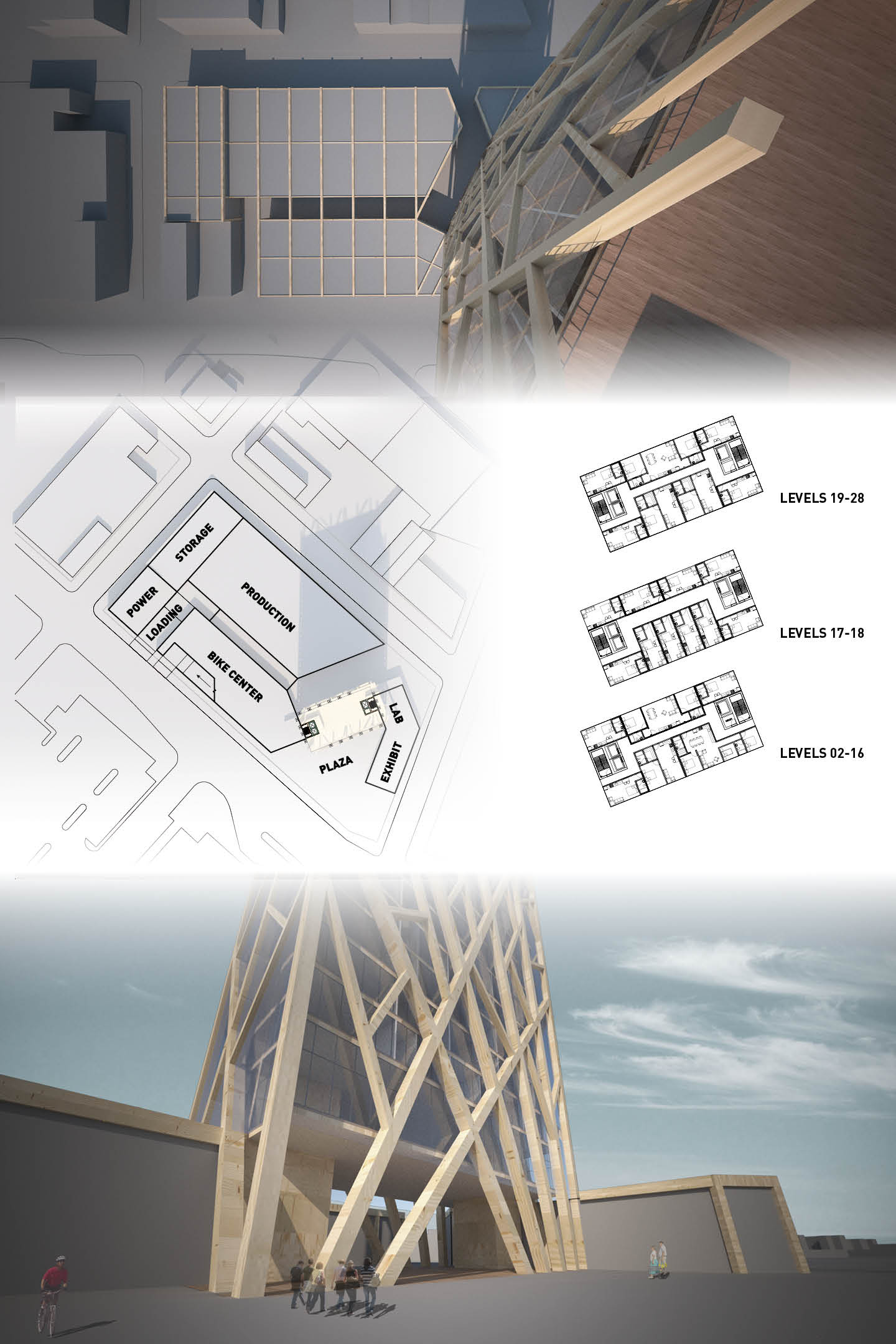

This is the structure of the tower as it stands for our mid-review today.

Moving Forward /

So the structure has changed a bit, turns out it was a bit too optimistic to expect the floor plates to span the original length. Next crit is Wenesday so major development is on hold to allow time to produce presentation boards this weekend.

Timber in the City Studio /

This semester of studies I am participating in a competition held by the ACSA called "Timber in the City." Tasked with designing a high-rise mixed used tower in Brooklyn, Red Hook specifically, we'll be exploring how to take Timber and other wood products well beyond their traditional capabilities.

This project will open up some creative options as structural timber in high-rise applications is still very young and looked with much skepticism Thanks to modern fabrication technology however, there should be an opportunity to either extend the performance of existing systems or develop an entirely new system to meet the design needs.

So far, we've embarked on the task of exploring the properties and origins of wood species, modern timber systems, looking at fabrication techniques and analyzing the small set of precedent buildings using timber in high-rise construction.

New products like CLT (cross laminated timber) and post-tensioned timber seem to be the most promising so far. Combined with 5-axis CNC routing or robotic assembly, this should be possible to produce in small runs with low overhead, opening up the possibility for the industrial space requirements in the competition to become a wood fabrication studio.

Overall, the project is very promising and the studio is excited about getting start on schematic design following our site research presentation next week.